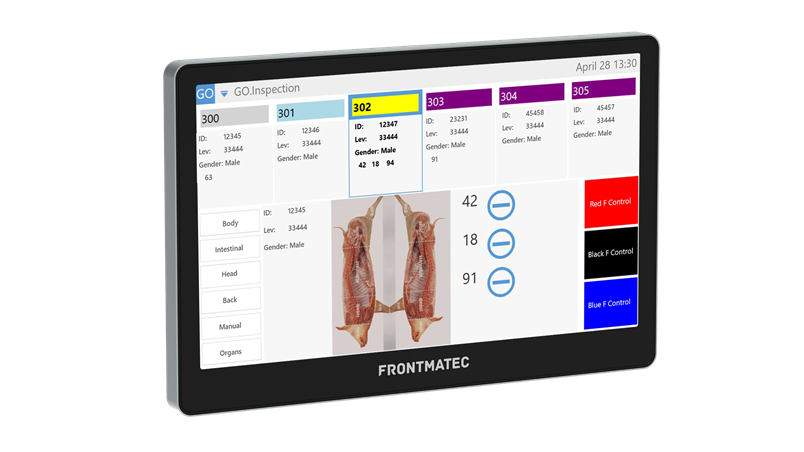

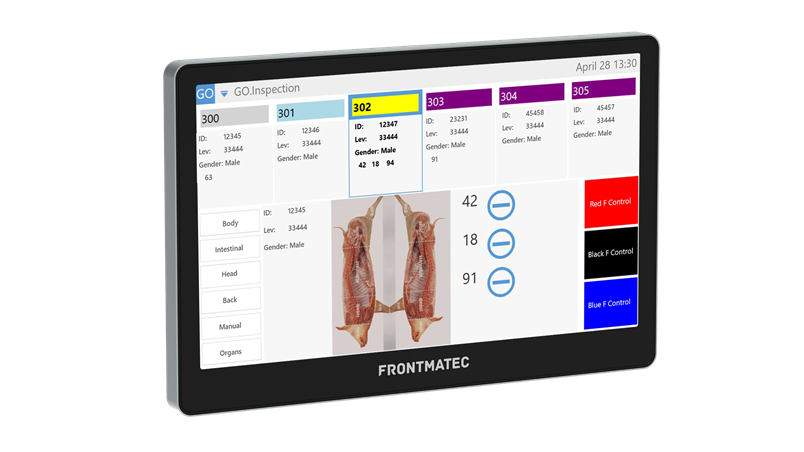

GO.Inspection is a general inspection and classification system for veterinarians.

The system tracks individual animals on one or more parallel conveyor systems, depending on how many parts the animal is split into – e.g. plucks and carcasses. A conveyor line is equipped with several touch panels that display the individual animals going by. While the veterinarians do the inspection of the animal they can easily register pre-configured sickness codes to the animal by a single touch on the panel.

In this way, a record of one or more codes are registered and reported to the individual animal. Depending on the speed, a number of veterinarians, and type of inspection the system can be equipped with as many panels as needed. When a carcass leaves the inspection area it will either be approved or classified as suspect based on the record of codes.

Depending on the category of codes the system will send the carcass to further inspection and handling in other inspection areas. Those post-inspection areas will also be equipped with touch panels and the same display of the individual carcasses.

GO.Inspection is a fully configurable system in terms of defining sickness codes, categories of codes, number of panels, number of post inspections, etc.

The veterinarian may add remarks for each carcass and make a final decision of the carcass's next destination. If approved the carcass will go directly towards the chill-room where it passes grading on the way. Alternatively, the veterinarian can redirect the carcass for the re-inspection. If the veterinarian does not make any selection on a carcass, then it is automatically approved.

EN

EN

English

English

中文

中文

Español

Español

Deutsch

Deutsch

Français

Français