Vertical Steam Scalding

The closed Frontmatec vertical steam scalding ensures optimal meat quality as steam is injected into the scalding cabinet and condensates on the carcass surfaces. The advantages of the vertical steam scalding are:

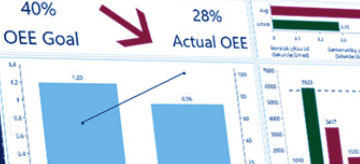

- Efficiency with a short start-up time

- Energy and water cost benefits with absolute temperature control and minimum energy and water consumption

- Improved work conditions and operators retention with user-friendly operating panel and lowering of the flooring plates for more space during work or cleaning

- Minimum risk of over-scalding during breakdown

EN

EN

English

English

中文

中文

Español

Español

Deutsch

Deutsch

Français

Français